Barcodes on Containers and Carriers

When conducting a run on the IAPS with ILASS, only use barcode types that employ a check digit to yield sufficient reading security. The preferred barcode symbology is Code 128. Code 39 Standard and Code 39 ASCII symbologies that employ a check digit are also acceptable. You can use up to six different container code types per application at the same time.

For each carrier used on the worktable, two carrier barcodes employing the Code 128 symbology identify each IAPS with ILASS carrier. The two barcodes together improve identification security for each carrier.

The information on the two barcodes is identical except for a single character alteration on the second barcode. The second barcode verifies the carrier ID. Software within the instrument stores the dimensions of the carrier. After matching the carrier ID with the database, the software can identify the properties of the carrier.

The barcode labels must adhere to the following specifications:

|

•

|

Use black symbols on a white background. |

|

•

|

Maintain a quality grade of A, B, or C according to ANSI X3.182 and DIN EN 1635 standards (with Grade A being preferable). |

|

•

|

Must be a module width of 0.127–0.381 mm (0.005–0.015 in). |

|

•

|

Ensure a quiet zone (QZ) of at least 5 mm (0.2 in). |

|

•

|

Ensure a minimum barcode height of 7 mm (0.28 in). |

|

•

|

Limit the barcode length to a maximum of 64 mm (2.52 in) excluding the quiet zone. |

|

•

|

Restrict the number of characters to a maximum of 32. |

To ensure accurate reading results, follow these additional recommendations:

|

•

|

Use a barcode testing device to verify the barcode quality. |

|

•

|

Use barcodes printed by a thermal-transfer or photographic printer. |

|

•

|

Make sure that the barcode label surface is matte and clean. |

|

•

|

Avoid using barcode labels that are yellowed, stained, creased, wet, or damaged. |

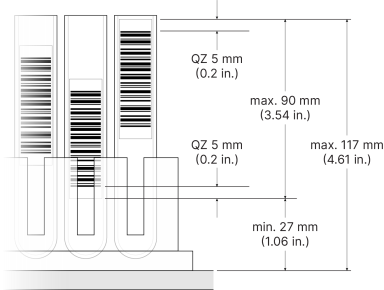

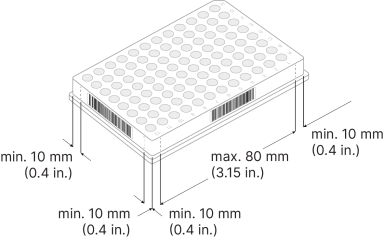

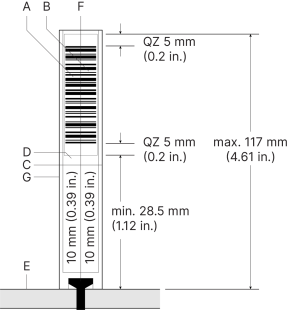

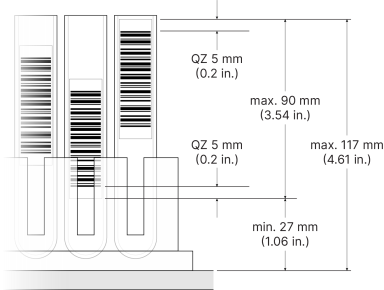

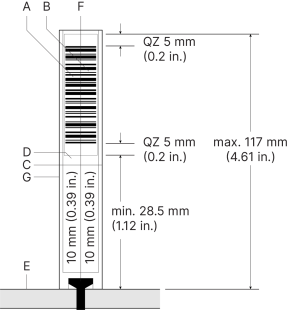

For guidance on barcode positioning on tubes, microplates, and carriers, refer to the following figures. QZ indicates the quiet zone of the barcode.

Barcode Label Positioning on Tubes

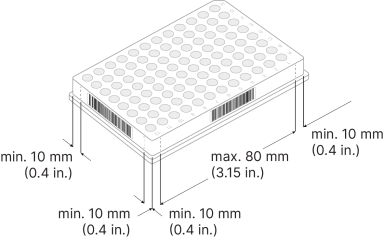

Barcode Label Positioning on Microplates

Barcode Label Positioning on Carriers

|

B.

|

Carrier ID Code 2 (for verification) |

|

C.

|

Maximum distance from pin center |

|

D.

|

Carrier barcode label support |

|

E.

|

Instrument worktable surface |

|

F.

|

Center of positioning pin |