Barcode Requirements

If you must print and position barcode labels for reagent or sample tubes, use the following guidelines.

|

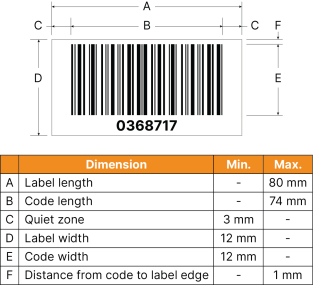

Specification |

Description |

|---|---|

|

Type |

Black bars with white background. |

|

Length of string |

Maximum 20 characters, excluding start, stop, and check characters. |

|

Code density, tolerance |

Minimum module width (x dimension) including a print tolerance: ≥ 0.1651 mm (0.0065 in) Maximum module width (x dimension) including a print tolerance: ≤ 0.508 mm (0.02 in) Best reading performance with x dimension: ≥ 0.254 mm (0.01 in) |

|

Number of check characters |

ISBT Standard: One character Code 128: One character Code 39: None Codabar: None Code 2 of 5 Interleaved: None UPC A/E: One character |

|

Quiet zone |

≥ 10 times the x dimension, but at least 3 mm (0.11811 in). |

|

Print quality |

A printed barcode with an ANSI/CEN/ISO grade A or B is required. Offset, typographic, intaglio, and flexographic printing are suitable. Mechanical dot matrix and Thermo matrix printing are not suitable. The surface can be treated, sealed, or plastic-coated. |

|

Alphanumeric text |

Illumina recommends generating a human readable portion for each barcode using alphanumeric text. Include this text on the printed barcodes. |

Barcode

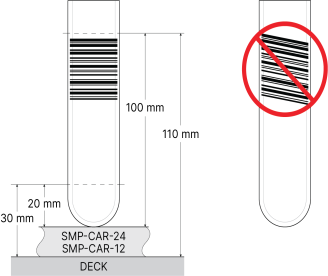

Place labels 20–100 mm (0.787–3.94 in) from the bottom of the tube at a 90° angle in the following figure. Make sure that the label is attached tightly over the entire length.