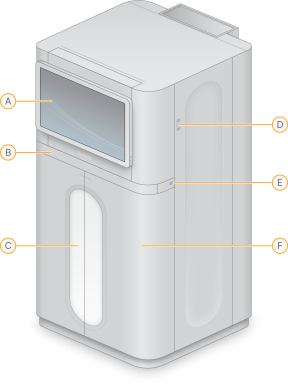

Instrument Components

The NovaSeq X Series comprises a touch screen monitor, a status bar, a power button with adjacent USB ports, and consumables compartments.

| A. | Touch screen monitor—Enables on-instrument configuration and setup using the NovaSeq X Series Control Software interface. To adjust the touch screen monitor height, use the buttons on the side of the monitor. |

| B. | Keyboard and trackpad tray—Extendable tray for keyboard and trackpad. Push the tray in to open. |

| C. | Status bar—Light color progresses as the system moves through its workflow. Blue indicates consumable loading, blue and purple indicate pre-run checks, and multicolor indicates sequencing. Solid red indicates critical errors. Red and white indicate other errors. |

| D. | USB 2.0 ports (3)—Provides access to USB connections for peripheral components. |

| E. | Power button—Controls instrument power and indicates whether the system is on (glows), off (dark), or off but with AC power (pulses). |

| F. | Liquids compartment—Contains reagent and buffer cartridges, and bottles for used reagents. |

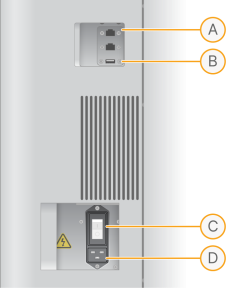

The back of the instrument has two Ethernet ports for an Ethernet connection and the switch and inlet that controls power to the instrument. Use the USB 2.0 port to connect a UPS.

| A. | Ethernet ports (2)—Ethernet cable connection. |

| B. | USB 2.0 port—USB connection for the UPS. |

| C. | Toggle switch—Turns instrument on and off. |

| D. | Power inlet—Power cord connection. |

The flow cell compartment contains the flow cell stage, which holds flow cell A on the left and flow cell B on the right. The compartment is located behind the instrument monitor. When loading the flow cell, the control software automatically raises the monitor.

An optical alignment target mounted on the flow cell stage diagnoses and corrects optical problems. When prompted by the control software, the optical alignment target realigns the system and adjusts camera focus to improve sequencing results.

The control software controls the opening and closing of the flow cell compartment door. The door opens automatically to load a flow cell.

Instrument includes pinch points. Moving parts can crush or cut. Keep clear of the moving door.

After loading, the software closes the compartment door, moves the flow cell into position, and vacuum seals and engages the clamps. Sensors verify the presence and compatibility of the flow cell.

Starting a run requires accessing the liquids compartment to load reagents and buffer and empty used reagent bottles. The two doors enclose the liquids compartment, which is divided into two matching sides for side A and side B.

The air filter covers the fan in the bottom drawer in the front of the instrument. Keep the front of the instrument clear of obstructions and floor clean to avoid clogging the air filter. Refer to Site Preparation for more information on placement.

The drawers have interior lights that signal when to remove the used cartridges and bottles. The lights turn off after the drawers are closed.

The instrument doors unlock automatically when loading sequencing or wash consumables during run or maintenance wash setup. When the instrument is not sequencing, you can manually unlock the instrument doors to change the air filter or to empty reagent waste outside of run setup. Refer to Replace Air Filter for more information.

| A. | Reagents drawers—Holds the reagent and buffer cartridges. |

| B. | Used reagents drawer—Holds the large and small used reagents bottles. |

| C. | Air filter compartment—Provides access to the replaceable air filter. |

The fluidics system is designed to route the reagent cartridge reagents, which are potentially hazardous, to the small used reagent bottle. Reagents from the buffer cartridge are routed to the large used reagent bottle. However, cross-contamination between used reagent streams can occur. For safety, assume that both used reagent bottles contain potentially hazardous chemicals. For detailed chemistry information, refer to the safety data sheet (SDS) at support.illumina.com/sds.html.